View what the 2025 agenda had in store below.

Maureen Kline is Vice President, Public Affairs and Sustainability for Pirelli Tire North America, responsible for the US, Canada and Mexico. She is based in Rome, Georgia.

She is a board member of the US Tire Manufacturers Association and the Tire and Rubber Association of Canada. She is on the Corporate Responsibility Steering Committee of the Automotive Industry Action Group, and on the Standards Advisory Group of the Sustainability Accounting Standards Board.

She writes a column on sustainability for www.Inc.com and is a frequent speaker on the topic. She teaches a course on Enterprise Sustainability within Clarkson University’s MS in Engineering Management program.

Previously she was based in Pirelli’s headquarters in Milan, Italy, where she coordinated government affairs for the company’s foreign subsidiaries, and before that was responsible for Pirelli’s international media relations.

Prior to her public affairs and communications career, Maureen worked as a journalist over a 15-year period. She was Milan correspondent for the Wall Street Journal Europe, Breaking Views, and Business Week, among others. She edited a blog on the topic of meritocracy, hosted by Italian daily newspaper Corriere della Sera. She wrote and co-hosted a TV talk show in Italy on business and finance, broadcast on the local channel Telelombardia.

Josh Guilliams, Vice President of Consultancy, leads Smithers’ technical consulting team based in Akron, Ohio. Josh manages client relationships and works with other Smithers experts on complex projects. He also conducts in-depth investigations of a wide variety of rubber materials and final products on behalf of clients.

Before joining the team at Smithers, Guilliams spent several years in leadership at Polymer Valley Chemicals, Inc., as Technical Director and Vice President of Technical Operations. Prior to his time at Polymer Valley Chemicals, he held technical and commercial roles at Hankook Tire, EASTMAN Chemical Corporation, LANXESS Corporation, and Bridgestone Americas Tire Operations.

With a diverse background in environmental law, policy, communications, non-profits, and business, Andy provides a unique perspective on strategy and execution for realizing sustainability impacts. He holds a B.A. from the University of Virginia, a M.S.E.L. from Vermont Law School, and J.D. from Case Western Reserve University School of Law.

Jacob George serves as a liaison to manufacturers in the automotive and tire industries on how information, intelligence and advisory services from Consumer Reports can be used in the product development and manufacturing areas.

Prior to this role, Jacob worked for Ipsos and J.D. Power in multiple roles primarily serving automotive clients in helping them to improve their product quality and customer satisfaction. His first job was with General Motors working in the manufacturing and product development areas. He holds a BSEE and MSEE from Purdue University and an MBA from University of Michigan and has three patents in advanced automotive technology areas.

Jay is the Director of Standards and Regulations for Continental Tire, the Americas located in Fort Mill, SC. He is responsible for all tire regulatory and standardization work throughout North and South America and represents Continental within numerous industry organizations including the Rubber Manufacturers Association and the Tire and Rim Association. Jay has been with Continental for over 15 years with leadership roles in product development, technical product management and racing development. He holds a degree in Mechanical Engineer from Clemson University - home of the 2016 College Football National Champions.

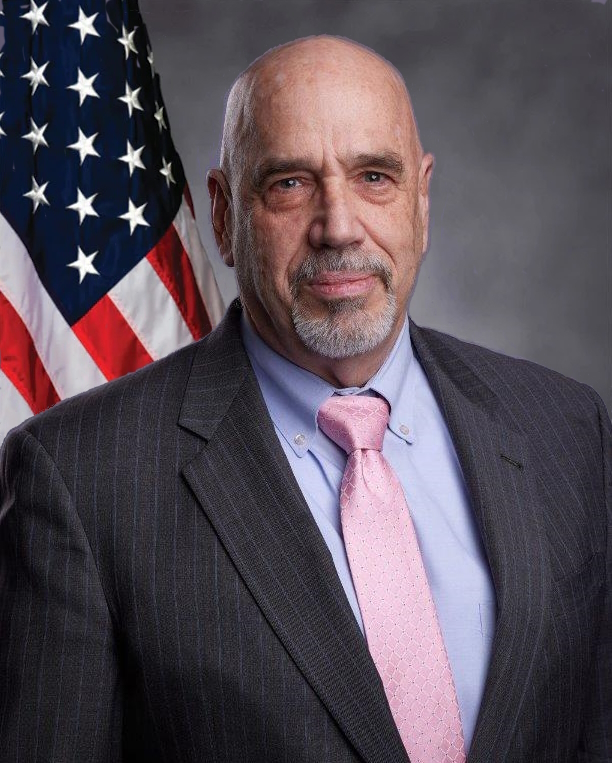

Otto Matheke has served as the Director of NHTSA’s Office of Vehicle Safety Compliance since March 2019. His responsibilities include leading test programs to determine vehicle and equipment compliance with safety standards, enforcing importation requirements and administering and enforcing the Corporate Average Fuel Economy (CAFE) program. He reports directly to the Associate Administrator for Enforcement and manages a staff of 35 and an $11.7 million annual budget.

A NHTSA veteran with over 35 years of experience, he has also served as Acting Chief Counsel for Litigation, Acting Director of the Office of Defects Investigation (ODI) and Acting Chief of the Trends Analysis Division of ODI. He began his federal career as a Trial Attorney in NHTSA’s Office of Chief Counsel in 1990 after being engaged in civil and criminal practice in Maine and New Hampshire.Mr. Matheke is a 1979 graduate of Middlebury College where he was elected to Phi Beta Kappa. He received his J.D. from Boston University in 1983. Otto has a Level 3 certification from the Professional Ski Instructors of America and teaches skiing part-time. In the summer months he can be found under the lift in his garage fussing with a 1986 Porsche 928.

Tatsuyuki Abe is a Sales Engineer at Kuraray America, Inc. He graduated from the University of Tokyo with a master's degree in Agricultural and Environmental Biology in 2015, and joined Kuraray Co., Ltd. in Japan as a Sales Representative in the same year. His career started with specific focus in elastomer products in Japan and then expanded to overseas business including China and Korea in 2018. In 2021 he relocated to Houston, TX for his new assignment at Kuraray America, Inc. He is currently focused on sales activities of Kuraray’s elastomer products in North and South America.

Serving as TRIB's Managing Director since 2010, Mr. Stevens has been focused on achieving TRIB’s mission of promoting and defending the tire retread and repair industries worldwide. Prior to joining TRIB, he served in a number of marketing and leadership roles for Fortune 100 companies in the US, Japan, and the United Kingdom. Mr. Stevens is a recognized global speaker for the retread industry having addressed audiences in the United States, Asia, Europe, and Latin America. He is a graduate of Trinity University, received his MBA from the University of Maryland, and holds the designation of Certified Association Executive (CAE).

-520_1.jpg?ext=.jpg)

Tom Bruton leads the Alternatives Analysis Support Unit in the Safer Consumer Products Program at the California Department of Toxic Substances Control. He received his Ph.D. in Civil and Environmental Engineering from University of California, Berkeley, where his research focused on cleanup methods for contaminated sites. Prior to joining DTSC, Tom was a Senior Scientist with the Green Science Policy Institute, where he served as a subject matter expert on per- and polyfluoroalkyl substances. Tom has two decades of experience related to environmental engineering, chemistry, and policy

He was a long time Board Member of the Tire Industry Association (TIA) and served as its President in 2005. Dick left Liberty Tire Recycling in 2021, when he was offered the position of Chief Executive Officer of the Tire Industry Association. Dick is frequently called upon by State Tire Dealer Associations, Industry Trade Groups and State Regulators to speak on various issues relating to the tire industry. He has been invited to provide his incite and industry experience to various Federal and State governmental Agencies, including the EPA, DOT, Department of Defense, U. S. Postal Service, The Georgia House Transportation Committee, Clemson University Tire Conference, Colorado Environmental Tire Conference, the California Recycling Conference and the White House Environmental Commission.

More recently, Dick was appointed by the Secretary of Commerce, Gina Raimondo, to serve on the Environmental Technologies Trade Advisory Committee (ETTAC) for the 2023-2024 charter.

Coming Soon

John began his career with Discount Tire Company in May of 2012 at the Corporate Office. John’s role for Discount Tire includes overseeing all aspects of Merchandising (sourcing, purchasing, assortment planning, retail pricing) for the company, Vendor Relationship Management of all tire, wheel, and non-merchandise vendors, and the Product Technical Team, which includes the Product Data Analytics group, the Product Quality Team, and the Product Fitment Team, which manages the Treadwell and the tire/wheel fitment guide. Prior to joining Discount Tire, John worked for Exponent, a scientific and engineering consulting firm. Before Exponent, John worked in the Research Laboratory of Ford Motor Company, where he became internationally recognized for his research on the topics of tire aging, tire test development, tire service life prediction, and the use of nitrogen as a tire inflation media. John has authored/presented over 40 papers on tire testing, has lectured in Europe and Asia, and holds 3 U.S. Patents.

Academic Credentials and Professional Honors

Ph.D., Polymer Science, The University of Akron, 1992

B.S., Chemistry, The University of Detroit, 1986

2009 Sparks-Thomas Award given by the Rubber Division of the American Chemical Society for ‘outstanding contribution to the science and technology of elastomers’.

Member of Sigma Xi; Certified Six Sigma Greenbelt

Former Adjunct Associate Professor of Chemistry, Oakland University in Rochester, Michigan

Mr. Sheerin is responsible for environmental, regulatory and legislatives issues relating to end-of-life tires. He represents the tire industry before state legislatures, and state agencies in rulemakings. He represents the industry as their expert on end of life tire issues, and he authors the biennial USTMA U.S. Scrap Tire Markets report.

He participates in various state, trade association and standard making committees to encourage markets for End-of-life tires addressing both annual generation and abandoned piles, and organizes conferences to grown and support scrap tire recycling. Before joining the USTMA in 2014, Mr. Sheerin was the Retail Environmental Director for Bridgestone Retail Operations, responsible for all the environmental aspects of the retail company including compliance management, environmental education, property related environmental issues, waste recycling and disposal and emergency situations.

Prior to that, he worked as a Professional Environmental Engineer. Mr. Sheerin holds a bachelor’s degree in civil engineering and his master’s degree in environmental engineering from the Illinois Institute of Technology. He is also a JD graduate of the Chicago Kent School of Law.

Nick Eulau is Executive Director of Guayule and End of Life Tire Recycling Business at Bridgestone. In this role, he is responsible for key sustainability business operations within Bridgestone’s West (Americas + EMEA) operations, including efforts to improve tire recycling outcomes within Bridgestone’s business operations.

He joined Bridgestone in 2017 and, prior to his role in Bridgestone’s sustainability business served in Corporate Development roles at the company.

Andrew Meurer serves as President and Chief Commercial Officer of Liberty Tire Recycling, bringing over 30 years of executive experience in manufacturing and consumer goods.

Meurer spent more than 12 years at Michelin, where he most recently served as Vice President of Sales for the North American Passenger Tire Division. His earlier career included leadership roles at Kimberly-Clark, and over two decades at Procter & Gamble, where he held various marketing and sales positions.

At Liberty Tire Recycling, Meurer leads efforts to collaborate with tire manufacturers and retailers on sustainable end-of-life tire solutions, focusing on cost-effective recycling methods and expanding markets for recycled tire materials

David Johansen has 27 years of experience in the tire industry, with expertise in tire design, testing and simulation, and manufacturing process control. David holds Bachelor of Science and Master of Science degrees in Mechanical Engineering from Michigan Technological University.

Hope Pegues is a Tire Performance Engineer at the Michelin Americas R&D Center in Greenville, South Carolina. She earned her Master of Science degree from Duke University in 2021 and soon after joined Michelin’s Tire Physics and Performance Modeling department. In her current role, she focuses on leveraging data to develop predictive systems and testing methodologies to better understand tire wear performance.